Stockpile Measurement

and Modelling

Using Drones for Volumetric Analysis

Faster Surveys. Smarter Decisions. Bigger Savings.

Get fast, precise stockpile measurements with no disruption to your operations. Reliable data for better inventory management, smarter planning, and stronger profits.

What is Stockpile Measurement?

Stockpile measurement and volumentric analysis refer to the process of quantifying the volume, mass, and value of stockpiled materials, such as aggregates, minerals, crops, or other goods stored in large quantities. This is a crucial task in industries like construction, mining, agriculture, and logistics, as accurate measurements are essential for inventory management, financial reporting, and operational planning.

Traditional Methods vs. Drone-based Measurement

Traditionally, stockpile measurement involve manual surveys or the use of ground-based equipment like laser scanners. These methods are time-consuming, labour-intensive, and can be prone to human error. In contrast, drones offer a faster, more accurate, more cost-effective, and much safer alternative. Every pixel of the high-resolution digital surface model (DSM) contains accurate coordinate information and can therefore be utilised to create far more detailed models than would be possible using traditional methods. Modelling and measurement can be done retrospectively on earlier data to generate comparisons to aid planning and decision making.

How Drones Work for Stockpile Measurement

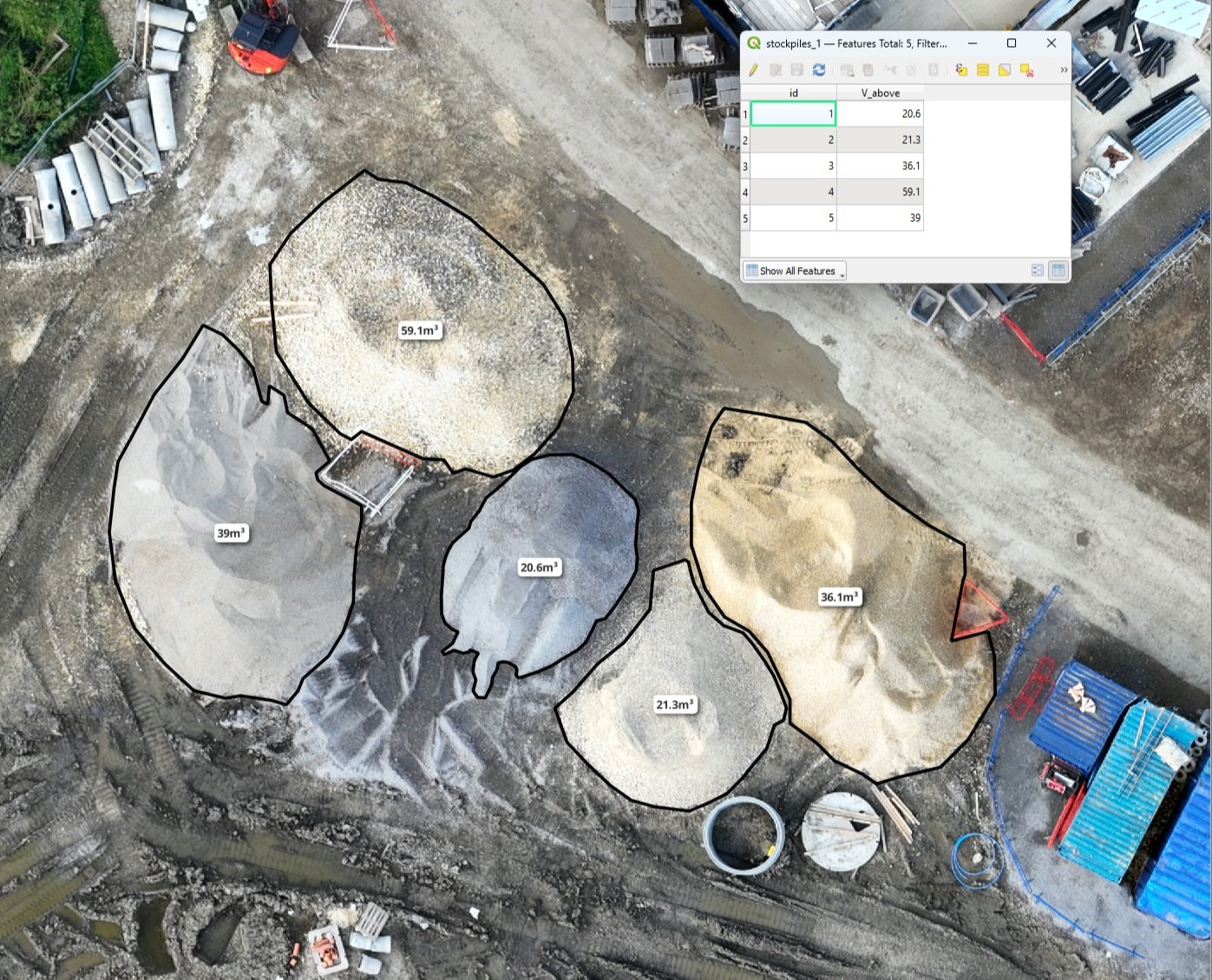

Our drones are equipped with high-resolution imaging sensors, allowing them to capture multiple detailed images from multiple angles and create detailed surface models of stockpiles using photogrammetry software. These models are then analysed using surveying or GIS software to calculate volume and dimensions. Outputs include vector shapefiles that can be directly imported into CAD software for further analysis and design.

To further enhance accuracy, ground control points (GCPs) are strategically placed markers on the ground with known coordinates. By incorporating GCPs into drone surveys, you can significantly improve the precision of stockpile measurements. This ensures that the data collected by the drone aligns accurately with the real-world coordinates, reducing potential errors. Existing site control points can be used when present to ensure further alignment with engineering drawings.

Benefits of Using Drones for Stockpile Measurement

Accuracy and Precision: Drones provide highly accurate measurements, reducing errors associated with manual surveys or ground-based methods. This leads to more reliable data for decision-making.

Time Efficiency: Drones can rapidly survey large areas in a fraction of the time required by traditional methods. This efficiency translates to faster data acquisition and quicker decision-making processes.

Safety: By eliminating the need for workers to physically climb stockpiles or navigate hazardous terrain, drones significantly enhance safety in the workplace.

Cost-effectiveness: Drones can lead to substantial cost savings by reducing labor costs, minimising equipment wear and tear, and improving overall operational efficiency.

Data Accessibility and Analysis: The data collected by drones is easily accessible and can be processed with specialised software, providing detailed reports and actionable insights for better inventory management.

Deliverables

Once the drone images of the stockpile have been processed using photogrammetry software, the standard outputs of digital surface model (DSM), Orthomosaic and 3D point cloud can be ulilised in other software applications to further insights and information. The stockpile can be accurately measured and modelled in software such as QGIS or Virtual Surveyor and the models can even be exported as dxf files which can be used in design applications such as AutoCAD and Sketchup. So from one quick drone flight you get:

High resolution imagery, typically 1cm/pixel GSD

3D model for enhanced visual inspection and analysis

Highly accurate volume calculations derived from hundreds of accurately measured points

Contour and Triangulated (TIN) models for use in design applications